ViewMold Co Ltd is an ISO 9001:2000 certified plastic injection molds company that supplies

plastic injection molds

plastic injection molds design

plastic injection molds manufacturing of high quality,plastic injection molding...

We are Proud to bring to you the quality and speed you would expect from Viewmold plastic injection molds. We believe we will be your supplier of choice. Just give Viewmold a

email or

submit a quote online.

Our team of quote specialists is the most responsive and the most hands on.

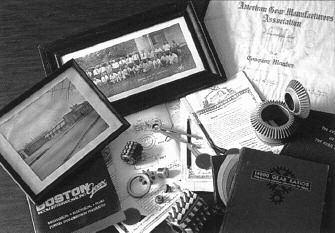

BOSTON?/span> The Boston Gear Story

21st Century Innovation Built on Our Second Century of Quality, Service,Value, and Performance

Started in 1877 as a machine shop making

gear cutting machines, Boston Gear has led

the growth of the power transmission industry

for more than a century. In its early years,

Boston Gear introduced the concepts of gear

standardization and stock gears?TM)innovation

of enormous benefit to power transmission

system designers, specifiers and users.

Today, Boston Gear manufactures open

gearing in our modern state-of-the-art

manufacturing facility in Charlotte, North

Carolina.

Wecontinue to improve product quality and

manufacturing efficiencies with implementation

of programs including Gear Cell Manufacturing,

CAD/CAM Design and Manufacturing, CNC/DNC

Programming, and Computer Aided Production

and Inventory Control.

In addition, Boston Gear provides the widest range of integrated motion control products

from one source.

The convenience of this single-source capa-

bility is yours when you buy Boston Gear.

Manufacturing Excellence

Boston Gear manufactures more than

20,000 products in-house at our facility in

Charlotte, North Carolina. We utilize cell

technology, efficient plant and work center

layouts, and operator teams. This approach

optimizes production flow, encourages a

sense of responsibility and pride of

workmanship, and enables consistently

high-quality output.

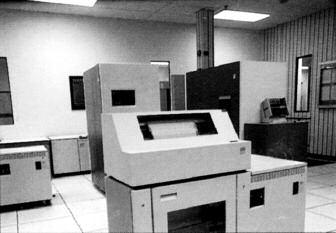

Computerized production control provides

close supervision over scheduling and

resource planning, allowing the flexibility

to fit your requirements smoothly into the

master schedule. Other dedicated computer

controls within the production department

govern the ordering and delivery functions

to keep operations lean and efficient.

Engineering Services

The Boston Gear Engineering Group can

satisfy your technical needs through skillful

application of standard products or

development of custom designs. Creating

specials if we are unable to satisfy your needs

from our stock catalog items or stock altered

items is an important aspect of customer

service. Support is provided by R&D

personnel who use microprocessor-

controlled equipment to collect and monitor

data on materials and product performance.

In-house heat treating facilities enable us to

harden gear teeth while maintaining a soft

bore for future correct sizing as determined

by the specific application.

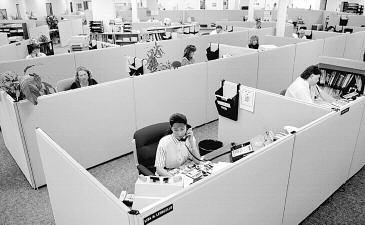

Customer Service

Service is our first priority at Boston Gear.

We provide service and support through a

network of the finest authorized distributors

backed by Boston Gear field sales and customer service inside sales personnel.

National Service Centers and distributors

are linked by a sophisticated computer

communication system which provides

product availability, and product

customization to meet your motion control

needs.

You get up-to-the-minute information on

product availability, order entry, delivery

dates and prices. You'sll save time and

be assured that your order is filled and

on its way.

Stock Availability

Boston Gear utilizes our Florence, Kentucky

Central Distribution Center to inventory and

ship all catalog products. This facility is

supplemented by satellite warehouses in

Norwalk, California; Mississauga, Ontario;

and Mexico City,Mexico. In keeping with our

intent to be the most responsive supplier in

the power transmission industry, Boston Gear

will ship any in- stock product the same day

it's ordered, up to 8p.m. EST

Quality Assurance

Boston Gear products are subject to an

in-house Total Quality Awareness System to

ensure that quality requirements are met

while productivity is improved. The objective:

make the product correctly the first time (R)C al

the time. In operation, our people audit

production processes, isolate problem

causes, then implement corrective action to

maintain and improve quality throughout the

production run. Our Quality Policy is your

assurance that Total Quality Awareness is

working.

Stock Product Alterations

Boston Gear provides customization services

for open gears and rack with 24-hour

turnaround. Our machine shop operations in

our Florence facility for product rework and

modification include:

Reduce faces and OD's

Rebore, shorten or remove hubs

Add keyways and set screws

Machine to special tolerances

Drill and tap

Stamp parts with customer's P/N

Why It Pays To Buy

Boston Gear

With over a century of experience, Boston

Gear has built an unmatched store of

knowledge and expertise in the design,

manufacture and improvement of power

transmission products. This unique capability

has been made more accessible and

cost-effective with the thoughtful application

of the latest in state-of-the-art computer

technology.

Choose from a vast array of stock products

described in the Boston Gear Product

Catalogs, or work with Boston Gear engineers

to find an economical solution to your special

requirements. Either way, you°Ore assured o

efficient, on-time order fulfillment to meet

your productivity demands.

For the best in quality, service, value and performance, it pays to buy Boston Gear (R)C Th

Market Leader and Innovator in Selected

Motion Control Products and Information

Related Services!